Our manufacturing capability for Tube Products embodies precision, versatility, and quality. With advanced machinery, versatile material options, customization capabilities, and a steadfast commitment to quality assurance and compliance, we stand ready to meet the diverse needs of industries ranging from automotive and Agriculture to Construction and Machine Tools. Whether you require standard tube products or customized solutions, you can trust UNIFLEX ® to deliver excellence every step of the way.

At UNIFLEX ®, we have in-house equipment that can cut tubes of all shapes and sizes of Carbon Steel, Stainless Steel, and Aluminium. We work with Band Saw, Circular Cold Saw and Lathe and after cutting a deburring and end finishing operation are carried out to ensure complete accuracy and tolerances prior to further use.

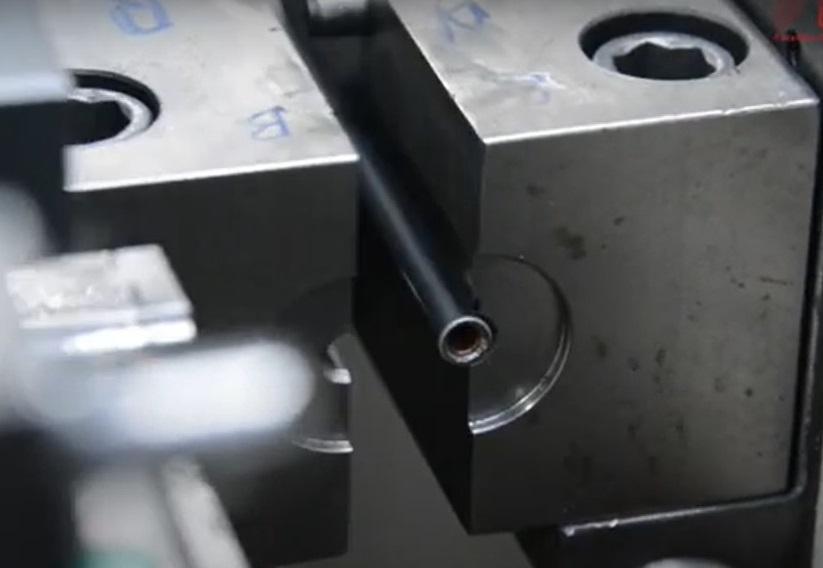

We offer a wide array of Tube End Forming capabilities including Swaging, Single & Double Flaring, Flanging, Beading, Spooling, Bulging, Chamfering, Crimping, Tapering, Notching, and Rounding. We can end form tubes from small hypodermic (capillary) up to 3.125” in diameter. We are equipped to end from all types of metal alloys including Steel, Aluminium, Copper, Brass, Stainless Steel, and others.

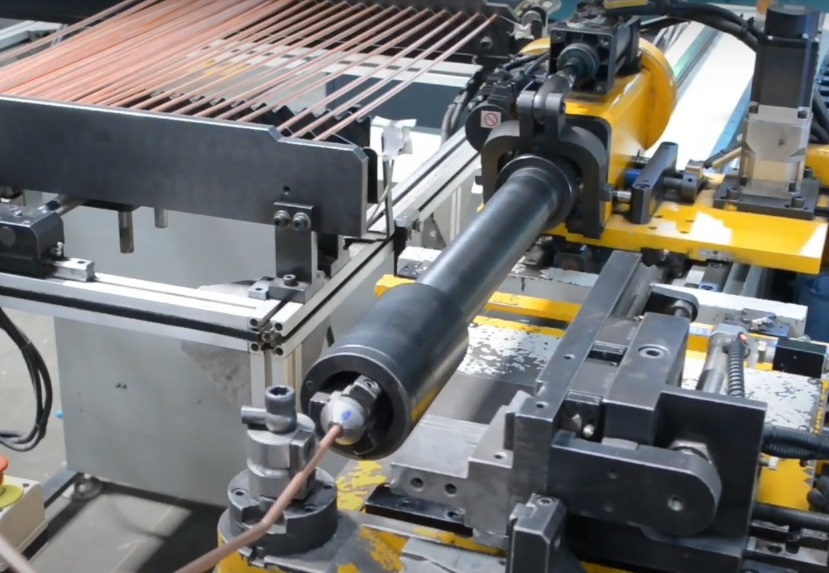

UNIFLEX ® is a full-service Tube Bending Operation offering full CNC tube bending of pipes and tubes ranging from 4 mm to 114 mm in diameter. Tube bending is done using multi-axes CNC Tube Bending, NC Tube Bending, or Manual Bending machines. We work with tubes in all grades of Carbon Steel, Stainless Steel, Copper, Brass, and Aluminium and pride ourselves in providing our customers with the highest quality tube and pipe assemblies with quick turnaround times. Whether you require a large volume production order or a prototype part, contact UNIFLEX ® today. We bend round tubes, square tubes, and various other extruded or drawn shapes. Capability includes 1D Bending as well as Infinite Radius Roll Bending.

Brazing can be accomplished either by manual brazing, induction brazing, or if feasible using the Conveyor Type Furnace brazing process.

UNIFLEX ® offers TIG, Orbital TIG as well as CO2 Welding capability. Welding is carried out by qualified welders specialized and well-trained to carry out their work efficiently to ensure a leak-proof weld joint.

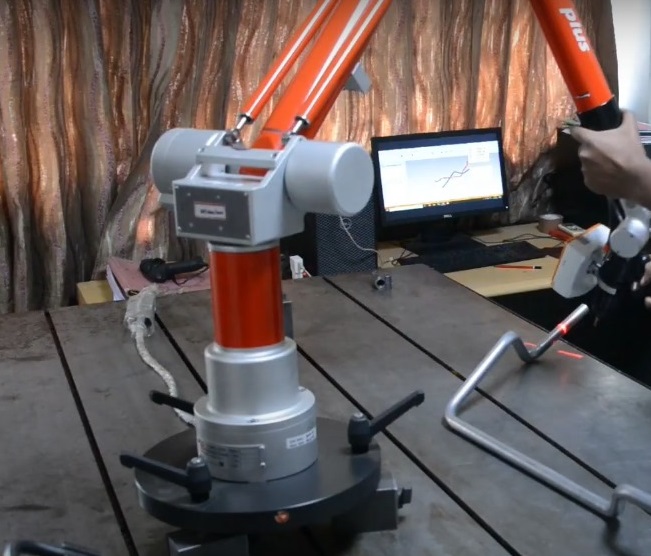

We utilize a CMM (Co-ordinate Measurement Machine) with tube scanning capability as well as a 3D scanner for reverse engineering as well as to ensure accurate prototypes. First article inspection reports are developed for new parts that allow the client to evaluate the design and final fit. Processes are in place that ensure accurate new part development from concept through the FAI phase to final production status on time.

Feel free to reach out to us via phone or by filling out the contact form below. Our dedicated representatives are committed to providing prompt and personalized assistance to meet your needs.

We value your interest in UNIFLEX® and look forward to hearing from you. Whether you have questions about our products, need assistance with a project, or want to explore partnership opportunities, our team is here to help.

+91-80-43580300/43580301

+91-80-43580331